View More

Home News Product News AODE high and low temperature liquid intelligent temperature control equipment, help IGBT chip test accurate temperature control

Home News Product News AODE high and low temperature liquid intelligent temperature control equipment, help IGBT chip test accurate temperature control

In the semiconductor industry, the performance of IGBT (insulated gate bipolar transistor) chips directly determines the efficiency and stability of the device. With the rapid development of new energy, power management and other fields, the demand for IGBT chips is growing, and the testing requirements for its performance are becoming more stringent.

Today, we want to share the story of A leading domestic power semiconductor company A to see how they solved the temperature control problem in IGBT chip testing through AODE's high and low temperature all-in-one machine.

Project background/Technology leading, but facing testing challenges

A company has strong technical strength, covering the whole process from power semiconductor chip design, processing, testing to application. Their IGBT products are widely used in special power supplies, frequency converters, induction heating equipment and other fields. At present, the company is actively expanding to the power management, new energy power generation and other markets, and with Europe, the United States, Japan and other international teams and well-known experts research and development, with first-class chip design capabilities and rich manufacturing experience.

In order to further improve the production capacity and technical level, the company prepared to build a production line of the latest generation of 8-inch IGBT chip back with an annual output of 60,000 pieces, and built a perfect testing platform and testing environment, and the test level has reached international standards.

However, with the expansion of production scale, laboratory testing requirements for IGBT chips are becoming higher and higher, especially in the high and low temperature environment stability test, has become an urgent problem to be solved.

Pain point analysis/accurate temperature control, perfect service is the key

The performance of IGBT chip under extreme temperature is directly related to its reliability under complex working conditions. Therefore, the laboratory needs a set of equipment that can accurately control temperature and flow to simulate the working state of the chip in different environments. However, the customer had not used similar high and low temperature test equipment before and was relatively new to this technology.

How to choose a device that can meet the requirements of high precision and provide quality service has become the primary challenge for customers.

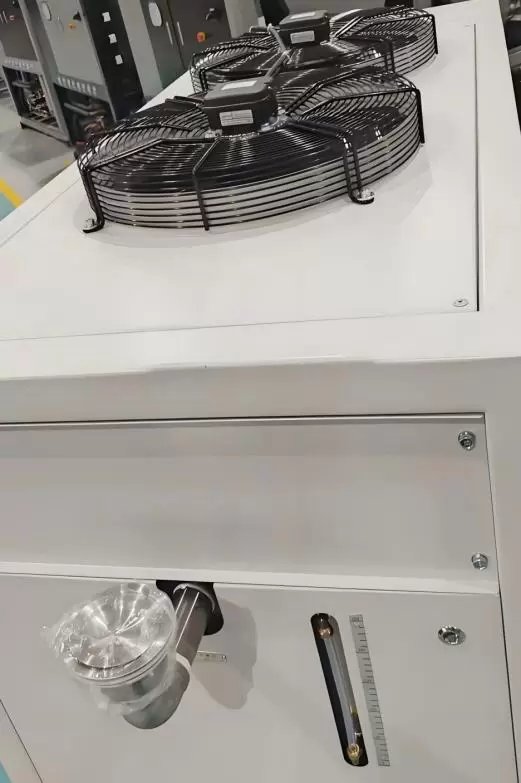

Solution/AODE high and low temperature liquid intelligent temperature control equipment

A company hopes to choose a large domestic brand to ensure the quality of equipment and after-sales service, to avoid the problem when the solution cycle is too long. After rigorous screening and evaluation, they finally chose ORD among many brands. Through communication and evaluation, AODE tailored the temperature control solution for Company A.

Double precision King fried combination

Control range: -10℃ ~ +120℃

Temperature accuracy: ±0.5℃ Flow control range: 7-70L flow accuracy up to ±0.2L

How it works: After the high and low temperature liquid intelligent temperature control equipment is connected to the power supply, the equipment advanced in-line circulation controls the temperature of the water tank to ensure that the temperature of the water tank reaches the set temperature. After reaching the set temperature, the frequency conversion pump pumps the corresponding medium into the customer's products according to the set flow rate. The high and low temperature liquid intelligent temperature control equipment thus continuously circulates to ensure that the temperature is controlled within the set value range and the constant temperature is maintained. More accurate control, so as to test the stability of the IGBT chip under different temperature and flow conditions.

From commissioning to after-sales, the whole worry

Temperature control equipment in the continuous use of the process, there will be some small problems, especially as a semiconductor IGBT chip test laboratory, the accuracy of the temperature flow is very strict. Whether the problem can be solved in time is the key.

A customer in the early use of the process of the problem, AODE after-sales staff positive response, within 24 hours of the plane rushed to the scene to solve the problem, but also gave A customer a good experience.

On the circuit of semiconductor chips, AODE proved the rise of domestic temperature control equipment with strength. We not only provide accurate and reliable solutions for IGBT chip stability testing, but also win high recognition from customers with excellent service. In the future, AODE will continue to break through the problems of the industry, and help the industry to better develop with the service purpose of international high standard design and high quality requirements.