Home

Case

Home

Case

Pain point

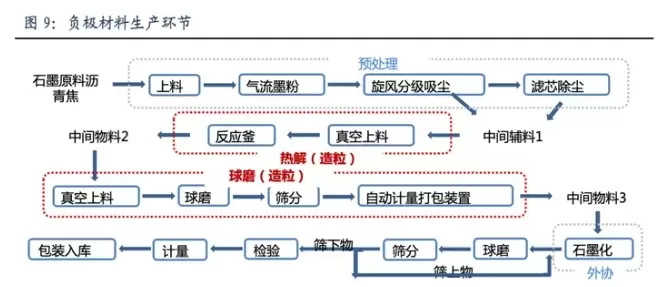

Around this new production line, Company A has put forward new high requirements for the reaction kettle and heat exchanger temperature control equipment in the production process of lithium anode materials, which needs to meet the high temperature of 380 ° C to polymerize the materials, and at the same time, after-sales service should arrive at the scene within 24 hours to solve the problem.

Solution (Select equipment)

AODE has communicated many times to deeply understand the technical needs of A company for temperature control equipment, as well as the service details including equipment installation, commissioning, maintenance, etc., and technological progress is inseparable from the application of production technology and high-tech supporting equipment. With the laying of A company's new process production line, there are also higher requirements for temperature control equipment. At present, industrial temperature control equipment service providers are generally unable to provide sophisticated 380 ° C mold temperature machine, but before AODE has been successful industry cases of 380 ° C mold temperature machine, which is one of the important factors that AODE can obtain the recognition of A company. In the face of high temperature, explosion-proof, high heating power needs, AODE output a complete set of customized solutions, including early communication, process design, communication cooperation, after-sales service.

AODE YGW-600D electric heating organic heat carrier boiler

● Temperature control range: room temperature +45℃ ~ 380℃ (design temperature 400℃)

● Temperature control accuracy: PID ±1℃

● Control mode: PLC man-machine interface

● Explosion-proof setting: circulating pump, oil pump explosion-proof

● Seven security protection:

Overtemperature: The heater temperature exceeds the upper limit. The air switch - trip cuts off the main power supply

Power phase reversal: power phase detection to prevent pump reversal and alarm indication

Motor overload: Thermal relay protects motor overload and gives alarm indication

Lack of media protection: The level switch detects the oil level of the oil tank, prevents lack of media and gives alarm indication

Pipe clogging: BY-PASS pressure relief loop protects pump

Abnormal pressure: The system automatically stops heating when the pressure is abnormal

Exhaust: When the equipment runs 120 degrees, the automatic stop heating timing exhaust function

Effect

For this project, AODE conducted in-depth communication and provided detailed equipment drawings and related information as needed. In the design process, the size and process parameters of the AODE equipment are integrated into the overall process package to ensure the design accuracy of the new special carbon-based resin production line, so that the production line can be quickly built, and the equipment and the overall process can be seamlessly connected to achieve efficient operation. Through the optimization and improvement of the production process, the product quality and production efficiency are effectively improved, laying a solid foundation for the successful implementation of the project.

Case scene (Photo)