View More

Home News Company News Is temperature out of control eating into profits? The 6 core technologies of AODE put a "temperature lock" on global industries.

Home News Company News Is temperature out of control eating into profits? The 6 core technologies of AODE put a "temperature lock" on global industries.

Is temperature out of control eating into profits? The 6 core technologies of AODE put a "temperature lock" on global industries.

Professional temperature control solutions

【Which vital industries is China's temperature control technology taking over?】

In the core essence of high-end manufacturing, temperature plays a decisive role.

A deviation of ±0.1℃ could mean the scrapping of millions of products; crossing the limits of hundreds of degrees in temperature difference is often the foundation of breakthrough technologies.

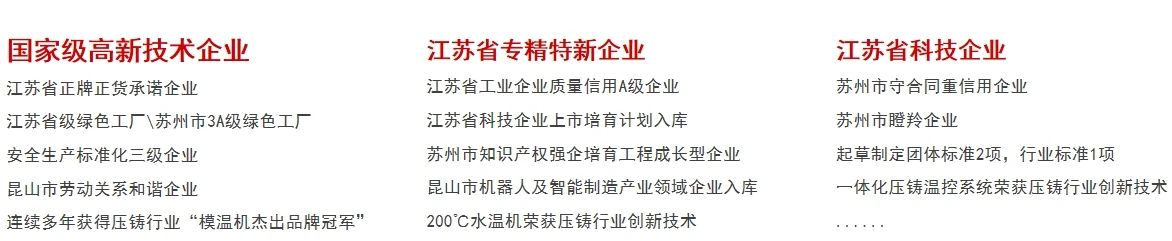

Suzhou AODE Precise Equipment Co.,Ltd as a leader in industrial temperature control solutions, has been deeply engaged in industrial temperature control technology for 21 years. With six core strengths, it has broken through the boundaries of temperature control and injected powerful and precise "temperature control vitality" into global high-end manufacturing, establishing a commanding position in the industry.

Six core strengths

Build an unbreakable barrier in temperature control

High temperature control accuracy

-Break through technological barriers and set industry standards

The temperature control accuracy can reach ±0.1℃, which is at the leading level in the domestic industry. It has successfully broken through the technological blockade imposed by Europe and the United States in the field of optical lenses.

Wide temperature control range

-Comprehensive coverage, meeting diverse needs

The temperature control range is from -120℃ to +400℃. The specially designed high and low temperature pump has a temperature tolerance range of -196℃ to +400℃. This wide temperature control range provides a comprehensive and continuous temperature control solution guarantee for various complex industrial processes ranging from cryogenic research to ultra-high temperature processing, meeting the diverse temperature control requirements of different industries.

The temperature control rate is fast

-Efficient switching, enhancing production efficiency

Aode's independently developed "Water/Oil Rapid Cooling and Heating Switching Technology" enables automatic temperature control for both rapid cooling and heating. It provides efficient and precise temperature control requirements for various industrial processes. The application of this technology not only enhances production efficiency but also ensures the stability of product quality.

safety and stability

-Green innovation is in line with national policies.

Aode has achieved significant improvements in heating/cooling efficiency through multiple innovations such as "high-efficiency low-nitrogen gas condensing boiler technology" and "VOCs condensation recovery refrigeration technology". These innovations help reduce nitrogen oxides and carbon emissions, aligning with the country's low-carbon and environmental protection policies. The application of these technologies not only enhances the energy efficiency of the equipment but also provides strong support for the sustainable development of the enterprise.

intelligent control

-Data-driven, achieving intelligent management

The products produced by Aode can all achieve intelligent control functions such as energy consumption detection, online monitoring, data analysis, remote control, and alarm linkage. The realization of these functions makes the equipment management more intelligent and convenient, and improves the management efficiency of the enterprise.

Hardcore Product Matrix

Transforming limits and precision into reality

# Breakthrough in Extreme Temperature Limits:

Challenging the impossible and setting new industry standards

01.200℃ WATER TEMPERATURE CONTROL UNIT

Product Introduction: Primarily used for integrated die-casting of automotive structural components, as well as in situations where environmental requirements are high and oil temperature machines cannot meet the needs. Its advantages lie in environmental friendliness, low operating costs, and high heat conduction efficiency.

02.400℃ OIL TEMPERATURE CONTROL UNIT

Product Introduction: The ultra-high temperature oil heating machine can reach a maximum temperature of 400℃. It is used in the 5G circuit board industry and meets the strict requirements for ultra-high temperature processing.

03.-120℃ DEEP CRYOGENIC CHILLER

Product Introduction: The lowest cooling temperature can reach -120℃. It is mainly used in the fields of chemical engineering and pharmaceuticals, providing reliable temperature control support for deep cooling research.

# Breakthrough in Precise Temperature Control:

Strive for excellence, contribute to high-end manufacturing

01.-90℃~250℃

HIGH AND LOW

TEMPERATURE INTEGRATED

MACHINE

Product Introduction: Temperature control accuracy ±0.1℃, Flow control ±0.2L. It is mainly used for the detection of new energy battery packs and in the semiconductor field, ensuring the high requirements of precise manufacturing.

02.180±0.1℃

WATER TEMPERATURE CONTROL UNIT

Product Introduction: Ultra-high temperature control accuracy, with a control accuracy of ±0.1℃. It is mainly used in the manufacturing of optical lenses. The requirements for cleanliness and transparency are very high, and the materials are expensive and cannot be recycled. They must be formed in one step, so the control accuracy is extremely demanding.

Suzhou AODE Precise Equipment Co.,Ltd with its six core technologies and a series of cutting-edge products that lead the industry, not only successfully broke through the technological blockade, but also set a new benchmark in the global precision temperature control technology field.

In the future, Aode will continue to be driven by innovation and customer needs, constantly pushing the boundaries of technology, to provide more precise, efficient and reliable temperature control solutions for the high-end manufacturing industry, and empower the future of global high-end manufacturing.