View More

Home News Company News 【Chemical New Materials】Explosion-proof, high cooling capacity and high energy efficiency, easy to maintain, AODE's integrated skid-mounted chiller unit

Home News Company News 【Chemical New Materials】Explosion-proof, high cooling capacity and high energy efficiency, easy to maintain, AODE's integrated skid-mounted chiller unit

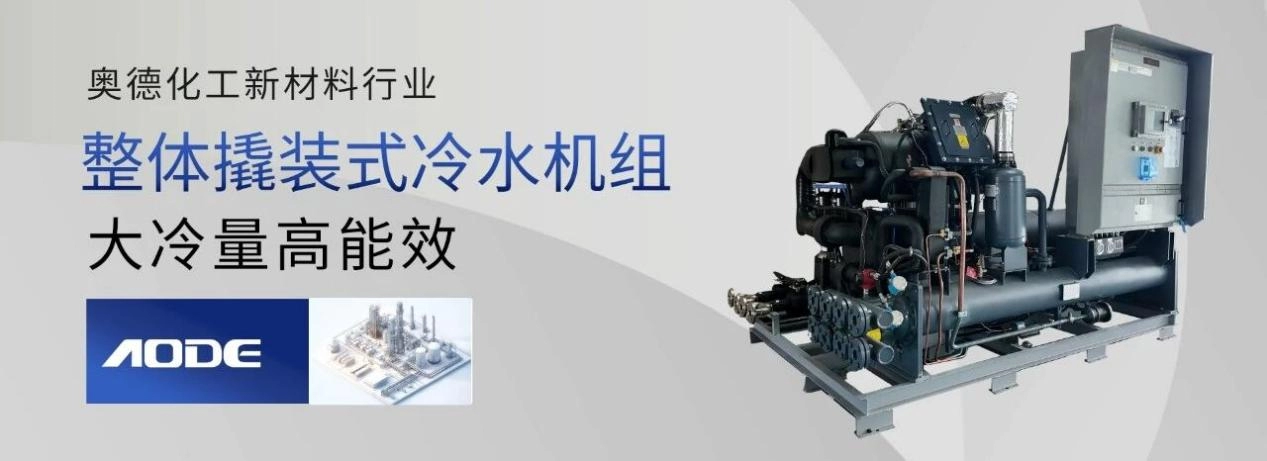

【Chemical New Materials】Explosion-proof, high cooling capacity and high energy efficiency, easy to maintain, AODE's integrated skid-mounted chiller unit

Temperature control solutions for new chemical materials

The chemical new materials industry is a high-end application field for air conditioners. Its demands are far beyond just "cooling", and include extremely strict requirements for temperature accuracy, stability, reliability, corrosion resistance and energy efficiency.

In the production process of new chemical materials, many reactions need to be carried out within specific temperature ranges to ensure the smooth progress of the reactions and the stability of product quality. When the reaction temperature fluctuates, it not only affects the reaction rate, but also may lead to a decline in product quality and even the production of substandard products.

Part 01

Industry pain points

Five core demands

Unlike traditional refrigeration, the requirements for water chillers in the chemical new materials industry can be summarized as "high, stable, durable, energy-saving, and intelligent":

1.High precision and high stability

Accuracy requirements: Many polymerization reactions (such as PPS, LCP, PEKK, etc.) are exothermic reactions. Temperature fluctuations of ±0.5℃ or even ±0.1℃ can significantly affect the molecular weight distribution, degree of polymerization, product color, and final performance (such as strength, heat resistance). The chiller unit must provide a constant and precise temperature.

Stability: The production process is often continuous. The chiller unit needs to have the ability to operate stably throughout the year without interruption. Any unexpected shutdown could result in the scrapping of the entire batch of products, causing huge losses.

2.High reliability and durability

Component quality: The quality and lifespan requirements for core components such as compressors, pumps, and valves are extremely high. Typically, the design lifespan is required to be over 10 years.

3.Strong corrosion resistance

Complex operating conditions: In an open system, cooling water may come into contact with leaked chemicals or be eroded by salt in coastal areas. Even in a fully enclosed system, water quality may change due to equipment corrosion or chemical penetration.

Material selection: Heat exchangers such as evaporators and condensers often use stainless steel (such as 304, 316L) or even titanium tubes to resist corrosion and ensure long-term sealing and efficiency of operation.

4.High efficiency and energy saving

Safe and Efficient: In environments with flammable and explosive substances, the equipment must achieve a high explosion-proof level while also maintaining low energy consumption.

Energy-saving Technology: Variable frequency speed regulation technology is widely favored in the industry. It can automatically adjust the compressor speed according to the actual heat load, achieving extremely high energy efficiency during partial load conditions, and has a significant energy-saving effect.

5.Intelligent control and remote monitoring

Precise control: Advanced PLC or microcomputer controllers can achieve multi-level energy regulation, fault warning, data recording and other functions.

System integration: Supports remote monitoring, data analysis and predictive maintenance.

Part 02

Technical breakthrough

Integrated packaged chiller unit

Facing numerous temperature control challenges in the chemical new materials industry, AODE leveraging its profound technical expertise and rich industry experience, has launched an integrated skid-mounted chiller specifically tailored for this industry:

Safety and explosion-proof

This modular chiller unit has an explosion-proof rating of BT4, which means it can operate safely and stably in hazardous environments where there are flammable and explosive gases, vapors, or dust.

High cooling capacity and high energy efficiency

It is equipped with efficient compressors and heat exchangers, which can provide a large amount of cooling capacity in a short time, meeting the high requirements for cooling capacity in the production process of new chemical materials. Its unique energy-saving design makes the unit consume less energy during operation, saving the enterprise a large amount of energy costs. The refrigeration temperature of this unit can reach as low as -35℃, which can meet the special requirements for low-temperature environments in some chemical material production processes.

Simple installation and maintenance

AODE packaged chiller also adopts an integrated packaged design, integrating the refrigeration system, electrical control system, water circulation system, etc. into a single packaged frame for transportation and installation in one piece. This design not only significantly shortens the installation period, reduces the workload and complexity of on-site construction, but also improves the stability and reliability of the unit.

In the chemical new material industry, which is extremely sensitive to "temperature", a reliable, efficient and safe cooling system is no longer an auxiliary equipment but the core productivity. The AODE modular packaged low-temperature explosion-proof chiller, with its four core advantages of "safety and explosion prevention, large cooling capacity, high energy efficiency, and quick deployment", precisely addresses the core pain points. It not only provides customers with excellent process guarantees but also brings significant economic benefits and competitive advantages.