Home

Case

Home

Case

Pain point

C company is committed to the research and development and production of intelligent pressing equipment and hydraulic machinery, and provides equipment for the field of automation intelligent equipment manufacturing. It is a leading enterprise in the field of hydraulic machinery and intelligent pressing in China. In recent years, the preparation technology of hot pressing raw materials has shown an obvious trend of diverse development, which has not only brought about the development and change of hot pressing technology, but also led to the innovation and change of hot pressing equipment system. With the continuous improvement of the production process of C company, the temperature control requirements for hot pressing molding are also getting higher and higher. C Company hopes to improve the product process through the introduction of new technology, and achieve the effect of cost reduction and efficiency.

Put forward the demand: the overall process requirements, 5 minutes from room temperature to 210 ° C, heat preservation and pressure for 5 minutes, then 3 minutes from 210 ° C to 80 ° C cooling, pick up and feed 2 minutes, the overall process needs to be controlled in about 15 minutes.

Solution (Select equipment)

AODE communicated with the technical engineering manager of C Company several times, coordinated the equipment process, and finally provided C company with the hot and cold oil switching equipment AFCH-75-98. First of all, the hot oil is heated to 250℃ 20-25 minutes in advance, and then enters the customer's mold, and the time of raising the mold temperature is controlled within 5 minutes in the case of high temperature oil, and then the heat preservation and pressure preservation are carried out. When cooling down, the hot oil system is switched to self-circulation and keeps the hot oil at 250℃. The original reserve of 250 liters of cold oil is quickly cut into the mold to quickly cycle the temperature out, the hot oil is quickly returned to the hot oil tank, and the cold oil tank has been kept in a cooling state.

Effect

After the cooperation between AODE and C company, the production process that originally took 30 minutes to complete is now reduced to 15-20 minutes, which greatly reduces the time and improves the production efficiency, while the more accurate temperature control effectively improves the forming effect and product quality of the carbon fiber hot pressing process.

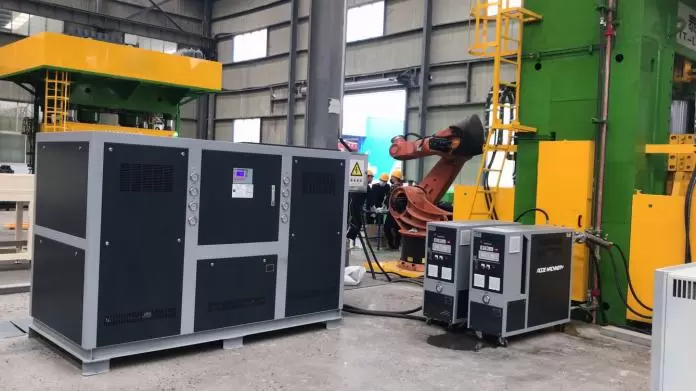

Case scene (Photo)