Home

Case

Home

Case

Pain point

Company D originally used the high temperature die temperature machine supported by the hot press manufacturer. Within one year of use, the fault caught fire twice, resulting in the failure of Company D to produce normally and serious safety risks. The original die temperature machine manufacturer could not solve the problem, so Company D urgently needed to find a safe and stable die temperature machine manufacturer to replace the original high temperature die temperature machine.

Solution (Select equipment)

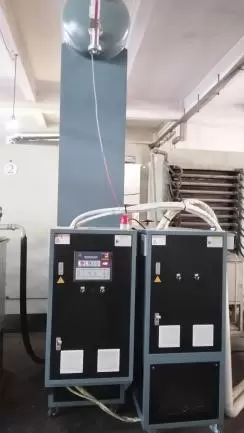

AODE first arranged after-sales personnel to go to the site to check, troubleshoot other brands of heaters on site, and finally confirmed that the heating equipment system design defect. In addition to the flaws in the system design, the original high-temperature die temperature machine did not have a cooling function. After collecting the relevant data and the process requirements of Company D, AODE proposed a customized solution to transport the high-temperature heat transfer oil furnace.

The high temperature heat transfer oil furnace uses efficient heat exchangers and pipe heaters to improve the heating and cooling rate, and quickly rise and fall the temperature. At the same time, the intelligent control system is equipped with a controller that automatically adjusts the temperature of the hot fluid according to the temperature sensor measurement of the hot fluid temperature or the internal temperature of the temperature control equipment to achieve high precision and intelligent temperature control.

Effect

One year after the replacement of the equipment, there was no fault in the mold temperature machine, and D Company was very satisfied with it and replaced the remaining host immediately.

Case scene (Photo)